Top Filling Machine Manufacturer in China

Machine is dedicated to providing professional and innovative solutions for filling machine manufacturing.

Advantages of Filling Machines

Machine supports numerous companies in Europe and the United States, with a focus on filling machines for over a decade.

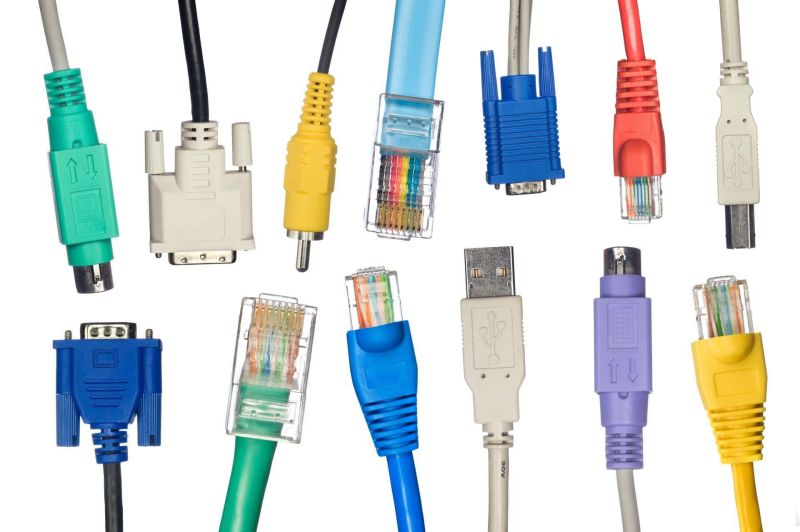

We offer diverse filling solutions, such as peristaltic, piston, screw, and ceramic pumps.

Our machines feature Panasonic servo motors for adjustable liquid volumes via touch screens. With a customizable speed range between 20 bpm and 300 bpm, our machines can fit various workshop sizes and weights.

Filling Equipment for Efficient Production

Our filling machine is highly adaptable and can accommodate bottles of any diameter. It comes with customizable options for 2, 4, 6, or 12 filling nozzles to efficiently meet your needs. This machine is particularly ideal for larger bottles, such as those used for hand sanitizer and cream.

Filling Machine for Rotary Bottles

Customization of the bottle feeding table, filling station, cap feed system, and capping system is recommended for a more effective outcome when using one or two types of bottles and caps.

Semi-Automatic Liquid Filling Machine

This machine is capable of efficiently filling roll-on massage oil bottles, providing an economical option for clients seeking initial investments. Operating this machine is simple and cost effective, particularly at low filling speeds.

Most Reliable Filling Machine Manufacturer in China

SourcifyChina MACHINE provides expert filling machine solutions for liquid and powder products. Our commitment to lifelong service ensures a win-win partnership with our clients.

We offer customized filling solutions tailored to your unique requirements, budget, and workshop area, ensuring stable and efficient production for enhanced marketability.

With over 300 successful filling and packaging projects completed, we possess extensive experience in foreign commissioning and installation, saving our clients both time and money. Please feel free to review feedback from our satisfied clients in Florida, USA.

Since 2013, this client from the United States has purchased numerous filling machines for both CBD and eliquid oil.

Related Products

Filling Machine Guide - Frequently Asked Questions

Avoiding Damage to Your Filling Machine

Owning a filling machine requires understanding its functions and ensuring its proper maintenance to avoid any harm to its functionality.

This article highlights 9 common mistakes that can cause permanent damage to your machine. Negligence such as over-filling or improper cleaning of the filling head can hinder its production and lead to costly repairs in terms of both time and money.

Common Error: Excessive Content

To ensure optimal performance of your filling machine, it is crucial to avoid over-filling.

This common mistake can have dire consequences, such as a breakdown of the machine or even a fire hazard. To prevent this, evenly spread the filling head across the bottle and apply just enough pressure to create a thin layer of wax.

It is important to use minimal force when pumping and ensure that there is minimal space between the filling head and the bottle’s rubber seal, depending on your machine’s specifications.

Preventing Overexertion Errors: Best Practices for Professionalism

Excessive force when pumping the filling head can result in oversaturation of the oil level in your bottle, hence causing stubborn leaks. To prevent such issues, limit the level of force applied to your machine while pumping.

This will enable you to regulate the pressure being distributed and facilitate proper sealing of your filling head.

Common Error: Insufficient Pressure

Proper absorption of CBD oil requires a thin film to be created across the wound surface, as it does not absorb as easily as water or other liquids.

If there is too much space between the bandage and filling head, the oil will not be absorbed properly, resulting in wasted product. To ensure even distribution, maintain constant pressure on the filling head throughout the pumping process.

For added support, a small rubber band can be used to tighten the bottle cap, but caution must be taken not to over-tighten and damage the machine.

Cleaning the Filling Head: Best Practices for Proper Maintenance

Proper cleaning is imperative to maintain the longevity of your machine. Over time, the oil and residue build-up can corrode the blade, making it difficult for oil to enter the bottle and create a thin layer of wax when exposed to air.

To avoid this, it is recommended to regularly clean your machine with isopropyl alcohol. Depending on usage, cleaning the blade should be done once a week or once a month. Failure to clean your machine properly can result in irreversible damage and costly repairs.

Avoiding Mistakes When Replacing Your Blade: A Professional Guide

Over time, the blade in your filling machine can weaken and become a potential point of failure. This can lead to uneven dispensing of CBD oil into the bottles, resulting in wasted product and subpar results.

To prevent this from happening, it’s important to periodically replace the blade with a new one to ensure even oil distribution. Not only does this save time and money, it also preserves the longevity and efficiency of your production line. In conclusion, regular checks and maintenance of your filling machine is essential to avoid common mistakes that can compromise the machine’s performance and reliability.

Investing in Filling Machines: A Professional Approach in Any Economy

The COVID-19 pandemic significantly impacted the global economy. During this time, there was a growing demand for medical marijuana and CBD oil. These products remained accessible through the use of machines like the one featured here.

However, with the current economic struggles we face, we may regret not taking advantage of these solutions sooner. While seemingly limited, there are still viable economic options available.

This particular machine is a reliable and efficient investment for individuals and can even be shared with others to maximize its affordability. For more detailed information, please read this article thoroughly before deciding to make a purchase.

Why Investing in a Professional Filling Machine is Essential

CBD, also known as “cannabidiol,” is a substance of increasing demand due to its medicinal properties. The internet has contributed to the widespread popularity of CBD oil and other forms of CBD across the nation. It is a natural oil supplement that can be safely consumed orally to treat a variety of human ailments.

CBD is extracted from the cannabis plant and then processed with an extraction machine. This oil has been used to address numerous health-related conditions, such as PTSD, epilepsy, and rheumatoid arthritis.

The high demand for this oil has resulted in increased prices, and medical dispensaries have taken advantage of the situation. The filling machine serves the main purpose of distributing the oil in the same location where it is extracted. Although the machine can also be used for extraction, it may be expensive for some users. An all-in-one solution can be achieved by investing in one of these machines, resulting in significant cost savings.

Is This a Wise Investment Decision for Me?

A machine like this one is essential when it comes to CBD oil. It’s worth investing in, as CBD oil will always be useful and popular.

Everyone can now access CBD without breaking the bank thanks to this machine. Whether it’s your first time or not, you can easily use it by following a few simple steps. There’s no need to read pages of instructions before operating it.

How Much Will It Cost?

This machine offers a highly affordable option for those seeking to produce their own high-quality CBD oil. With everything taken into consideration, including shipping and handling fees, the price is already reasonable without needing any discounts or promotions. As a professional CBD oil machine business owner, it’s important to invest in a machine that produces the highest volume of oil possible to maximize profit.

Learning the ins-and-outs of operating and selling CBD oil, as well as how to run an efficient business, are crucial skills for success. In conclusion, filling machine businesses remain highly profitable and in-demand, making them a solid investment for those with the necessary skills and equipment to operate effectively.